Privacy Cookie Policy

Policy concerning the processing of personal data in compliance with Regulation (EU) 2016/679 and with other legislation applying to the users of this website and cookie policy of the website: cibustec.it

This page describes how the aforementioned website is managed with regards to the personal data of the users consulting it. This is information to data subjects on personal data protection. This information is given having regard to the aforementioned website only and does not concern any other websites that could be consulted through links on this website, for which the Data Controller is in no way responsible or liable. The information given herein concerns especially the collection of personal data on the Internet in order to identify the minimum measures that shall be implemented to assure data subjects that these practices are fair and lawful.

Data Controller KOELN PARMA EXHIBITIONS SRL, Viale delle Esposizioni 393 – 43126 Parma (ITALY) P.IVA 02787300348 email: info@cibustec.com

Processed data

Personal and identifying data

‘Personal data’ means any information relating to a natural person identified or identifiable, including indirectly, by reference to any other information, including a personal identification number; ‘Identifying data’ means personal data that permit the direct identification of the data subject (e.g. forename, surname, email address, phone number).

Navigation data

The information systems and software procedures required for the proper functioning of this site will acquire, during normal operation, some personal information whose transmission is implicit in the use of internet communication protocols. These data are not collected in order to be associated with identified data subjects, but, by their very nature, could, by being processed and associated with data held by third parties, make it possible to identify users. This category of data includes IP addresses or domain names of the computers used by the users that connect to the website, URI (Uniform Resource Identifier) addresses of the resources requested, request time, method used to submit the request to the server, size of the response file, numeric code indicating the status of the response given by the server (successful, error, etc.) and other parameters regarding the operating system and the user’s IT environment. These data are used only to obtain anonymous statistical information on website use and to check that it is functioning properly. Defence in legal proceedings – The User’s Personal Data may be used for legal purposes by the Data Controller in court or in the stages leading to possible legal action arising from improper use of this application or the related services. The data may be used to ascertain liability for any cybercrime offence committed the detriment of the website. Maintenance – The User’s Personal Data may be processed using additional procedures and for additional purposes related to system maintenance.

Data provided voluntarily by the user

The optional, explicit and voluntary sending of an email to the addresses indicated on this site involves the subsequent acquisition of the sender’s address, which is necessary to respond to any requests, as well as any other personal data provided. Specific policies will be presented on the website pages in relation to particular services or processing of the personal data provided by the User or the Data Subject.

Cookie

Please refer to the bottom of the document, under heading: cookie policy.

Purposes of the processing for which consent is granted where requested

Personal data provided voluntarily will be processed for the following purposes, until an objection is made:

- performance of transactions strictly connected and instrumental to the management of relations with users of or visitors to the site;

- collection, storage and processing of data for:

- statistical analysis, including in anonymous and/or aggregate form;

- statistical analysis aimed at verifying the quality of the services offered by the site;

Methods used for processing – Storage

The processing will be carried out by automated means and manually, with methods and tools aimed at guaranteeing maximum security and privacy, by subjects specifically authorised to do so.

Storage period

The data will be stored for a period no longer than that required for the purposes for which the data are collected and subsequently processed.

Scope of disclosure and dissemination

The data processed will not be disseminated, sold or exchanged with third parties without the express consent of the data subject. The data may be disclosed to third parties belonging to the following categories:

- Parties that provide information system management services

- Parties that provide information system management services

- Competent Authorities in order to comply with statutory obligations and/or provisions issued by government bodies, upon request

- External providers

- Firms that carry out ordinary and extraordinary maintenance of the website

Your data will not be disseminated

Transfer of data to third countries

The personal data of the data subject will not be transmitted to third countries. In the event that transfer of the personal data to third countries or international organisations should become necessary in the future, all the provisions of Chapter V (Regulation EU 2016/679) shall be complied with in order to guarantee an adequate level of protection.

Rights of data subjects

Data subjects have the right to obtain from the Data Controller access to their personal data, rectification or erasure of such data as well as the right to obtain restriction of to object to processing. You also have the right to obtain full specification of your rights by writing to the Controller’s address.

Right to lodge a complaint with a supervisory authority

If you believe that processing of data concerning you violates your dignity, you have the right to lodge a complaint with the competent Supervisory Authority.

Cookie Policy

The software applications used may contain “cookie” technology. The primary function of cookies is to facilitate the user’s browsing. Cookies may provide information about browsing on the site and enable the functioning of certain services that require the various pages of the site viewed by the user to be identified. For access to the portal independently of the presence of a cookie, the browser type, operating system (e.g. Microsoft, Apple, Android, Linux), host and URL of the visitor are recorded, as well as the data pertaining to the requested page. In any case, the user may configure their browser settings to inform them when a cookie is received and thus decide to delete it. Further information about cookies can be found on the websites of the relevant browser providers.

What are cookies?

Cookies are small text files stored in the user’s computer when they visit certain web pages. In most browsers, cookies are enabled. The information necessary to change your browser’s cookie settings can be found below. Cookies are not harmful to the device on which they are stored. The cookies that we generate do not store identifying personal data, but we use the information they contain to improve users’ visits to our site. For example, they are useful for identifying and resolving errors.

Cookies can perform various functions, such as helping a user to browse the various pages efficiently, and can generally improve a user’s experience. The Data Controller reserves the right to use cookies, with the user’s consent, where required by the law or applicable regulations, to facilitate browsing on this site and to personalise the information that appears. The Data Controller also reserves the right to use similar systems to collect information about users of the site, such as browser type and operating system used, for statistical or security purposes.

Types of cookies

Cookies can be divided into two categories: “session” and “persistent”. Session cookies, having been downloaded, are then erased when the browser is closed, whereas persistent cookies are stored until they expire or are deleted. The session cookies we use aim to speed up web traffic analysis and facilitate users’ access to the services offered by the site. Session cookies are primarily used during authentication, authorisation and browsing within services accessed via sign-up. Most browsers are configured to accept cookies. If you do not wish to accept cookies, you can change your computer settings to reject them or display a warning when they are stored. If the data subject rejects the use of cookies, some of the site’s functionalities may not operate correctly and some services may not be available. The use of session cookies is strictly limited to the transmission of session identifiers, which are necessary to enable secure and efficient exploration of the site. These data are of a technical nature and are valid temporarily, and are not collected for the purpose of identifying users. However, through their functioning and in combination with other data held by third parties (e.g. the data subject’s internet service provider), they may allow users to be identified. First-party cookies can be read only by the domain that created them.

The cookies we use:

|

Technical navigation cookies

|

These cookies guarantee the normal navigation and use of the website and allow the connection between the server and the user’s browser.

These cookies are indispensable for browsing (for example, session identifiers) which allow the main features of the site to be used and to protect the connection. Without these cookies, the site could not be used normally.

|

|

Functional cookies

|

These cookies are stored in the computer or other device which, based on the user’s request, records the user’s choices, to allow them to be memorized in order to optimize and provide an improved and personalized navigation within the service or access to this site. (example: registration in restricted areas, storage of the products in the cart to have the possibility of finding them in the next session, saving the selected language, viewing a video or the possibility of commenting on the blog etc.). Functional cookies are not essential to the functioning of the site, but they improve the quality and experience of navigation.

|

|

Analytical cookies

|

These cookies collect information on how the user uses the website, such as which web pages are visited most often. This site uses third-party cookies “Google Analytics”. Google Analytics is a site of statistics, for example it calculates the number of visitors, what kind of technology they are using (for example Mac or Windows), how much time they spend on the site. All data collected is anonymous and in aggregate form therefore not profiling. The information generated by the cookie about the use of the website by the user (including the IP address) is transmitted and stored on Google’s servers.

Useful addresses to better understand the Google Analytics privacy policy: – http://www.google.com/analytics/terms/it.html

http://www.google.com/privacypolicy.html

Analytical cookies are not essential to the functioning of the site.

|

|

Cookies related to Social Network widgets

|

Widgets: These are all those components of a user interface of a program, which aims to facilitate the user in interacting with the program itself. During access, cookies may be installed that allow the user’s social account to interact with this site. These cookies are not essential for the operation of the site. The most common use is to share the contents of social networks. The presence of plugins involves the transmission of cookies to and from all sites managed by third parties. The management of the information collected by “third parties” is governed by the relevant information to which reference should be made. To ensure greater transparency and convenience, the web addresses of the various information and cookie management methods are given below.

Twitter informative: https://support.twitter.com/articles/20170514

Youtube informativa: YouTube informativa: http:// it.youtube.com/it/privacy

Linkedin: https://www.linkedin.com/legal/privacy-policy?_l=it_IT

|

|

Cookies that provide interactive maps

|

These cookies allow you to include interactive maps on this site. www.avdreform.it uses Google Maps. For information on Google Maps cookies http://www.google.co.uk/intl/it_IT/policies/

These cookies are not essential for the operation of the site.

|

How can I disable cookies?

Warning: if the user disables all types of cookies (including technical cookies), some of the site’s functionalities may become reduced or unavailable.

Most browsers automatically accept cookies, but you can choose not to accept them. If you do not want your computer to receive and store cookies, you can change the security settings on your browser (Internet Explorer, Google Chrome, Mozilla Firefox, Safari, etc.). There are several ways to manage cookies and other traceability technologies. By changing your browser settings, you can accept or reject cookies or decide to receive a warning message before accepting a cookie from the websites you visit. You can delete all the cookies installed in your browser’s cookie folder. Each browser has different setting management procedures.

Cookies can be disabled directly from your web browser. For more detailed information about cookie disabling options, below is a list of links for the settings of the most popular browsers.

If you do not use any of the browsers listed above, select “cookies” in the relevant section of the guide to find out how to locate your cookie folder.

Consent

By continuing to browse after having seen the short information note, the user is freely expressing their consent. However, said consent can be withdrawn at any time, and the user can proceed to disable cookies as described above.

Other links

In order to provide users with a better service, this site may contain links to other websites. The Data Controller disclaims any liability with regard to the content and material that can be accessed on such sites or that can be in any way obtained via the sites. Any information concerning the sites accessible via the links must be addressed exclusively to the administrators of the sites in question.

Changes to the cookie policy

Our cookie policy is periodically reviewed to ensure that it is always up to date. The latest update to this cookie policy took place on 23/10/2019

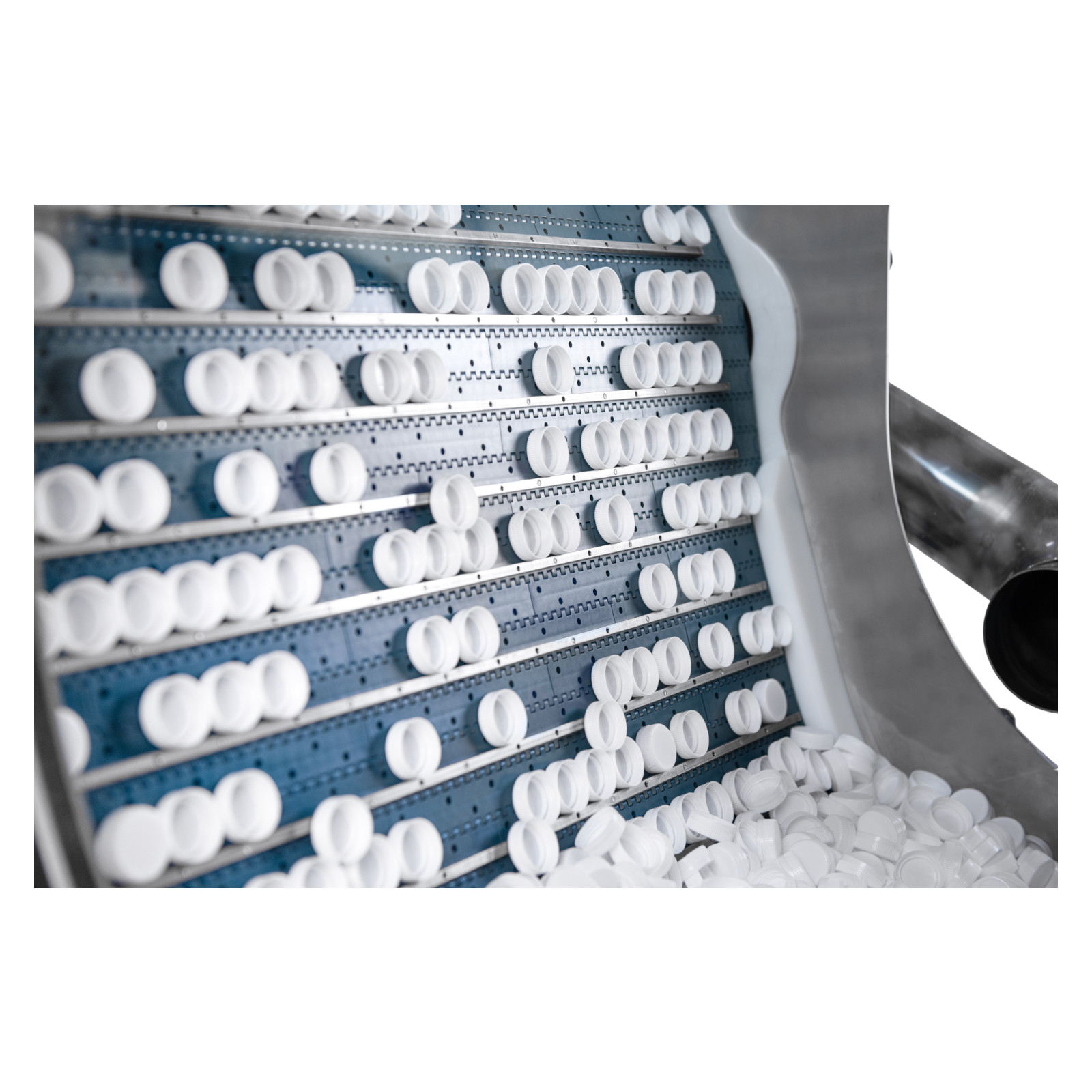

CCS - Continuous Cap Supply

CCS - Continuous Cap Supply FEC - Full Electronic Capper

FEC - Full Electronic Capper